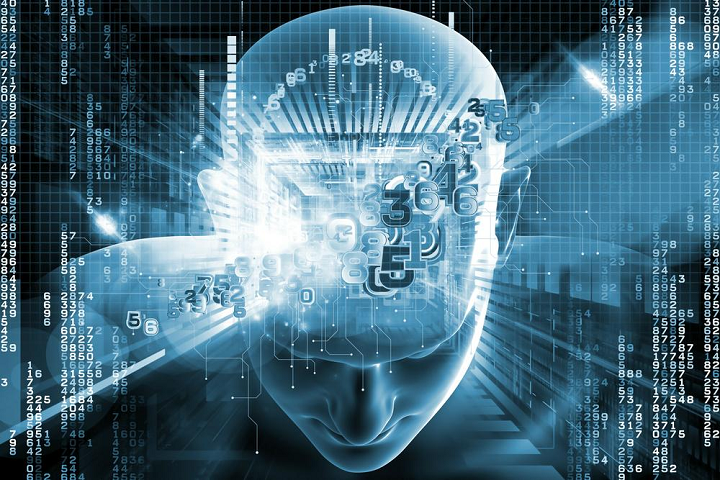

The world of Artificial Intelligence (AI) is rapidly evolving and becoming increasingly important in our lives. AI is a form of technology that enables machines to think and act like humans, and it has the potential to revolutionize the way we live and work.

The world of Artificial Intelligence (AI) is rapidly evolving and becoming increasingly important in our lives. AI is a form of technology that enables machines to think and act like humans, and it has the potential to revolutionize the way we live and work.

AI is already being used in a variety of ways, from self-driving cars to virtual assistants. AI can be used to automate mundane tasks, such as scheduling appointments or managing customer service inquiries. It can also be used to analyze large amounts of data and make predictions about the future.

AI is also being used to create more personalized experiences for customers. For example, AI can be used to analyze customer data and create personalized recommendations for products and services. AI can also be used to create more efficient and accurate customer service experiences.

It is also being used to create more efficient and accurate medical diagnoses. AI can be used to analyze medical images and detect diseases and conditions more quickly and accurately than humans. AI can also be used to analyze patient data and create personalized treatment plans.

Artificial Intelligence is also being used to create more efficient and accurate financial services. AI can be used to analyze financial data and make predictions about the stock market or other investments. AI can also be used to create more efficient and accurate banking services.

AI is also being used to create more efficient and accurate manufacturing processes. AI can be used to analyze manufacturing data and create more efficient and accurate production processes. AI can also be used to create more efficient and accurate supply chain management.

AI is also being used to create more efficient and accurate security systems. AI can be used to analyze security data and create more efficient and accurate security systems. AI can also be used to create more efficient and accurate facial recognition systems.

AI is an incredibly powerful technology that has the potential to revolutionize the way we live and work. As AI continues to evolve, it will become increasingly important in our lives.

chris@amberhill.biz

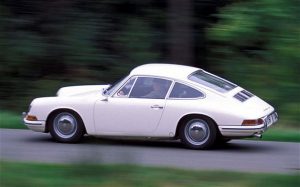

The U.K Governments decision to ban the sale of new petrol & diesel cars by 2030 presents some real challenges for the UK Automotive industry. A development lifecycle of 5-7 years is not unusual for a brand new model & when we are looking at a whole different powertrain & chassis with the consequent implications for production assembly then we are talking major developments.

The U.K Governments decision to ban the sale of new petrol & diesel cars by 2030 presents some real challenges for the UK Automotive industry. A development lifecycle of 5-7 years is not unusual for a brand new model & when we are looking at a whole different powertrain & chassis with the consequent implications for production assembly then we are talking major developments. A recent survey in

A recent survey in  Sir James Dyson has revealed what many automotive industry insiders already knew by rumour – his company is developing an Electric car ! The fact that Dyson have no automotive precedence or manufacturing facility should not be seen as a show stopper – there is plenty of subcontract capacity available (at a price) although his timescale of 2 years to volume manufacture is probably over ambitious.

Sir James Dyson has revealed what many automotive industry insiders already knew by rumour – his company is developing an Electric car ! The fact that Dyson have no automotive precedence or manufacturing facility should not be seen as a show stopper – there is plenty of subcontract capacity available (at a price) although his timescale of 2 years to volume manufacture is probably over ambitious. In the U.K today salaries have barely risen in real terms in the last decade & despite decreasing unemployment many find themselves in the precarious position of holding short term contracts with minimal security.

In the U.K today salaries have barely risen in real terms in the last decade & despite decreasing unemployment many find themselves in the precarious position of holding short term contracts with minimal security. commute we used to gather our thoughts and prepare for the day ahead is lost forever to the ever encroaching working day – whatever happened to ‘working from home’ ?

commute we used to gather our thoughts and prepare for the day ahead is lost forever to the ever encroaching working day – whatever happened to ‘working from home’ ?