Hey there, kids! Have you ever heard of something called “DevSecOps”? It might sound like a strange and complicated word, but don’t worry, we’re here to explain it in a way you can understand.

Imagine you have a special secret box where you keep all your toys, and you want to make sure it stays safe. DevSecOps is like taking care of that secret box, but for computer programs and apps.

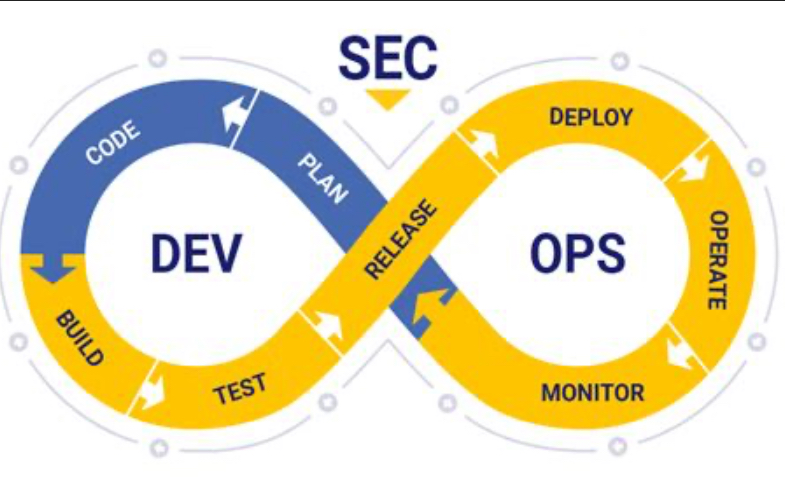

Let’s break it down into three parts: “Dev,” “Sec,” and “Ops.”

1. Dev (Development):

When people create computer programs and apps, they are like toy builders. They design, create, and build these digital toys. In the world of DevSecOps, this is where everything starts.

2. Sec (Security):

Just like you want to keep your toys safe in your secret box, computer programs need to be safe too. This part of DevSecOps is all about making sure the digital toys are protected from bad things, like hackers. Think of it as putting locks on your secret box or having guards to watch over your toys.

3. Ops (Operations):

Now, after building and securing the digital toys, we need to make sure they work smoothly. This is like making sure your toys are ready to play with whenever you want. It’s all about taking care of your toys and keeping them in good shape.

DevSecOps is like a team of grown-ups working together to create, secure, and take care of these digital toys. They build them, make sure they’re safe, and keep them running well. This way, people can use these digital toys without worrying about any problems.

So, in simple words, DevSecOps is about creating, protecting, and taking care of computer programs and apps, just like you do with your toys. It’s a way to make sure everything works well and stays safe in the digital world.

Now you know what DevSecOps is, and you can think of it as a big group of helpers making sure your digital toys are awesome, secure, and ready to play with!

chris@amberhill.biz

www.amberhill.biz

The U.K Governments decision to ban the sale of new petrol & diesel cars by 2030 presents some real challenges for the UK Automotive industry. A development lifecycle of 5-7 years is not unusual for a brand new model & when we are looking at a whole different powertrain & chassis with the consequent implications for production assembly then we are talking major developments.

The U.K Governments decision to ban the sale of new petrol & diesel cars by 2030 presents some real challenges for the UK Automotive industry. A development lifecycle of 5-7 years is not unusual for a brand new model & when we are looking at a whole different powertrain & chassis with the consequent implications for production assembly then we are talking major developments. Nissan recently returned to work at it’s Sunderland Plant following an announcement about a post Covid worldwide restructuring which will see the closure of its Barcelona Plant & commitment to Sunderland as a manufacturing centre for Quashqai & Juke SUV’s & could also produce their Renault counterparts the Kadjar & Capture.

Nissan recently returned to work at it’s Sunderland Plant following an announcement about a post Covid worldwide restructuring which will see the closure of its Barcelona Plant & commitment to Sunderland as a manufacturing centre for Quashqai & Juke SUV’s & could also produce their Renault counterparts the Kadjar & Capture. — Geely group has invested in Lotus heavily & the company has a tight well targeted product range including the fantastic new all electric hypercar the Evija. The company has also benefited from picking up a number of talented & experienced engineers from JLR.

— Geely group has invested in Lotus heavily & the company has a tight well targeted product range including the fantastic new all electric hypercar the Evija. The company has also benefited from picking up a number of talented & experienced engineers from JLR. Sir James Dyson has revealed what many automotive industry insiders already knew by rumour – his company is developing an Electric car ! The fact that Dyson have no automotive precedence or manufacturing facility should not be seen as a show stopper – there is plenty of subcontract capacity available (at a price) although his timescale of 2 years to volume manufacture is probably over ambitious.

Sir James Dyson has revealed what many automotive industry insiders already knew by rumour – his company is developing an Electric car ! The fact that Dyson have no automotive precedence or manufacturing facility should not be seen as a show stopper – there is plenty of subcontract capacity available (at a price) although his timescale of 2 years to volume manufacture is probably over ambitious. In the U.K today salaries have barely risen in real terms in the last decade & despite decreasing unemployment many find themselves in the precarious position of holding short term contracts with minimal security.

In the U.K today salaries have barely risen in real terms in the last decade & despite decreasing unemployment many find themselves in the precarious position of holding short term contracts with minimal security.