- “We poured gasoline on our own burning platform. I believe we have lacked accountability and leadership to align and direct the company through these disruptive times. We had a series of misses. We haven’t been delivering innovation fast enough. We’re not collaborating internally. Nokia, our platform is burning.” – Stephen Elop, CEO Nokia.

The recent internal memo “leaked” from Nokia & published on technology website Endgadget.com demonstrates the need for any corporation, but particularly those in the Technology arena, to have a continuous stream of new product developments flowing to the market. This is the direct result of a new product routemap which clearly identifies Customer needs, market trends and technology requirements.

The recent internal memo “leaked” from Nokia & published on technology website Endgadget.com demonstrates the need for any corporation, but particularly those in the Technology arena, to have a continuous stream of new product developments flowing to the market. This is the direct result of a new product routemap which clearly identifies Customer needs, market trends and technology requirements.

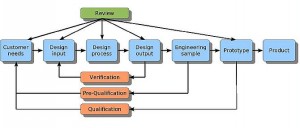

New Product Development should not be a haphazard process but one which is planned years in advance. It should also be adaptable to allow flexibility in the case of new technological or market developments.

Not so long ago Nokia held pole position in the mobile phone market with huge market share. Now they are languishing behind Apple & others in the

Smartphone arena and are struggling to compete with Chinese manufacturers at the bottom end of the market.

However, all is not doom and gloom. The new CEO Stephen Elop obviously

recognises the problems and is keen to address them. This is the key important step in any recovery. Rather than just bury his head in the sand he is tackling the issues head on which is good news for Nokia empoyees and shareholders.

If you need help with your product development process get in touch NOW!

; Keep up to date by becoming a facebook

fan

First of all please let me apologize for the use of the word “buggers” which some of you may find offensive but I just couldn’t think of another term (apart from an even more offensive B term) to describe those people who are just plain damn awkward.

First of all please let me apologize for the use of the word “buggers” which some of you may find offensive but I just couldn’t think of another term (apart from an even more offensive B term) to describe those people who are just plain damn awkward. When we think of Six Sigma we often picture “widgets” and manufacturing processes. This is because of the history of Six Sigma snd it’s origins with Motorola and electronics manufacturing.

When we think of Six Sigma we often picture “widgets” and manufacturing processes. This is because of the history of Six Sigma snd it’s origins with Motorola and electronics manufacturing.

Henry Ford once commented that if he’d asked his customers what they wanted they would have replied “Give me a faster horse”.

Henry Ford once commented that if he’d asked his customers what they wanted they would have replied “Give me a faster horse”. The Mac TV was released in 1993 and was Apple’s first attempt to integrate the functionality of a P.C with a cable ready T.V. Unforthunately it’s slow bus speed of 16 MHz made for a slow P.C compared to it’s rivals and a very expensive T.V at over $2000. Needless to say it flopped and only 10k were produced.

The Mac TV was released in 1993 and was Apple’s first attempt to integrate the functionality of a P.C with a cable ready T.V. Unforthunately it’s slow bus speed of 16 MHz made for a slow P.C compared to it’s rivals and a very expensive T.V at over $2000. Needless to say it flopped and only 10k were produced. Apple’s first attempt at a portable computer was the Macintosh portable. Released in 1989 it was way ahead of its time, and so it should have been at a whopping $6500. It weighed in at a hefty 7.2kg and had an active matrix LCD screen which was fantastic but the major contributor to its cost.

Apple’s first attempt at a portable computer was the Macintosh portable. Released in 1989 it was way ahead of its time, and so it should have been at a whopping $6500. It weighed in at a hefty 7.2kg and had an active matrix LCD screen which was fantastic but the major contributor to its cost. In 1995 Apple licensed its PIPPIN technology to Bandai to make a PC based game consol. The only problem was the competition, SEGA, SONY, Nintendo and PC based systems were already dominating the market. Only 42,000 PIPPIN units sold and it was withdrawn from the market.

In 1995 Apple licensed its PIPPIN technology to Bandai to make a PC based game consol. The only problem was the competition, SEGA, SONY, Nintendo and PC based systems were already dominating the market. Only 42,000 PIPPIN units sold and it was withdrawn from the market.

I was recently asked “how do you deal with negative customer feedback ?”

I was recently asked “how do you deal with negative customer feedback ?”