Prior to volume launch of a product it’s always a good idea to review the project paperwork.

Check the risk log to ensure all have been mitigated against.

Check the project plan, no outstanding tasks to be completed.

Check Design and Process FMEA’s to make sure all concerns have been addressed.

Review Project costs, making sure they are they on track.

Then call the Chinese Elfish subcontractors and thank them for their efforts. The adoption of Lean manufacturing techniques certainly helped to reduce costs and improve efficiencies and the product quality is certainly a damn site better, with SPC now in place on key processes we should expect ppm level failures on all toy manufacturing lines next year.

OK, the Reindeers are now fed and watered, breath visible in the cold still air, hooves pawing the frozen ground in anticipation, antlers glistening and clanking together.

The sledge is loaded, harnesses in place. Presents and parcels of every shape bulging out like walnuts in a sack.

The air is still and crisp, the stars twinkle in the deep, deep blackness of night. A faint tinkling of bells.

A last puff on the pipe, the long beard as white as the virgin snow against the deep red of the cape.

A crack of a whip and the sleigh begins to move across the hard ground, faster, faster increasing pace as the icy breath of the wind rustles through fur and fleece.

At last the hissing of the sleighs runners fades as it lifts into the air, the white landscape recedes and the sky gets even blacker, the stars shine like crazy diamonds.

“Now, Dasher! Now, Dancer! Now, Prancer, and Vixen! “On, Comet! On, Cupid! On, Donder and Blitzen!”

A faint cry echos across the frozen landscape…….

“A Merry Christmas to all and to all a Good Night !”

Most people involved in

Most people involved in

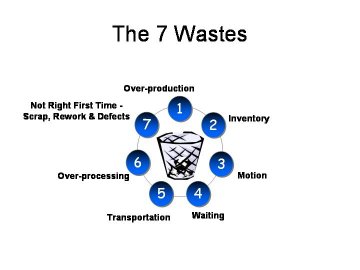

In their iconic book “Lean Thinking” Womack & Jones identified 5

In their iconic book “Lean Thinking” Womack & Jones identified 5

First of all please let me apologize for the use of the word “buggers” which some of you may find offensive but I just couldn’t think of another term (apart from an even more offensive B term) to describe those people who are just plain damn awkward.

First of all please let me apologize for the use of the word “buggers” which some of you may find offensive but I just couldn’t think of another term (apart from an even more offensive B term) to describe those people who are just plain damn awkward. When we think of Six Sigma we often picture “widgets” and manufacturing processes. This is because of the history of Six Sigma snd it’s origins with Motorola and electronics manufacturing.

When we think of Six Sigma we often picture “widgets” and manufacturing processes. This is because of the history of Six Sigma snd it’s origins with Motorola and electronics manufacturing.