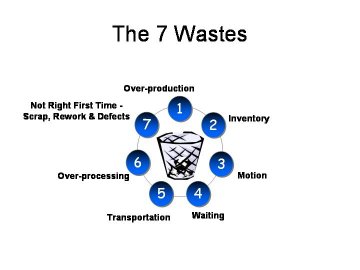

Toyota’s Taichi Ohno identified seven main sources of waste to be minimized in a Lean production system:-

Transportation

– the unnecessary movement of parts or materials. In our modern system of globalization where components are manufactured in many different parts of the world and transported to be assembled in a geographically remote location the opportunities for unnecessary transportation are endless. To minimize transportation waste we need to carefully analyze the origin of constituent parts and to identify opportunities for re-sourcing more local to final assembly.

Inventory – unnecessary inventory may as well be bags of cash. The operation needs to be streamlined to create a continuous flow minimizing inventory.

Motion – Any motion which is not adding value is Muda (waste) – for example if an operator has to repeatedly bend down to pick up a component this is unnecessary waste. The workstation should be designed to minimize unnecessary motion.

Waiting – time wasted whilst waiting for components, instructions, tools, indeed anything which is needed to maintain continuous flow is waste. If your organization is a service provider bear this in mind when designing systems to interface with customers. We all know the frustration of time wasted in a phone queue.

Overproduction – any production over and above the exact quantity the customer ordered is waste. The manufactured quantity should be pulled by the customer order.

Over-processing – the over embellishment or addition of none functional packaging is waste to be avoided and eliminated. What does the customer really want ?

Defects – all are waste and should be eliminated by the judicious use of 6 – sigma tools and Kaizen.

There are many other kinds of waste, which ones have you observed in your organization ?

When we think of Six Sigma we often picture “widgets” and manufacturing processes. This is because of the history of Six Sigma snd it’s origins with Motorola and electronics manufacturing.

When we think of Six Sigma we often picture “widgets” and manufacturing processes. This is because of the history of Six Sigma snd it’s origins with Motorola and electronics manufacturing.