Lean has a branding problem.

Mention the word in a boardroom and you’ll often see the same reactions: polite nods, a faint sigh, and a quiet fear that someone is about to roll out a set of Japanese words, coloured sticky notes, and a six-month programme that doesn’t quite touch the real work.

That’s a shame, because at its core Lean is neither complicated nor performative. It’s practical. It’s human. And when done well, it’s quietly transformative.

Lean is not about tools

Most organisations meet Lean through its artefacts: value stream maps, stand-ups, A3s, kanban boards. These are useful, but they’re not the point.

Lean starts with a much simpler question:

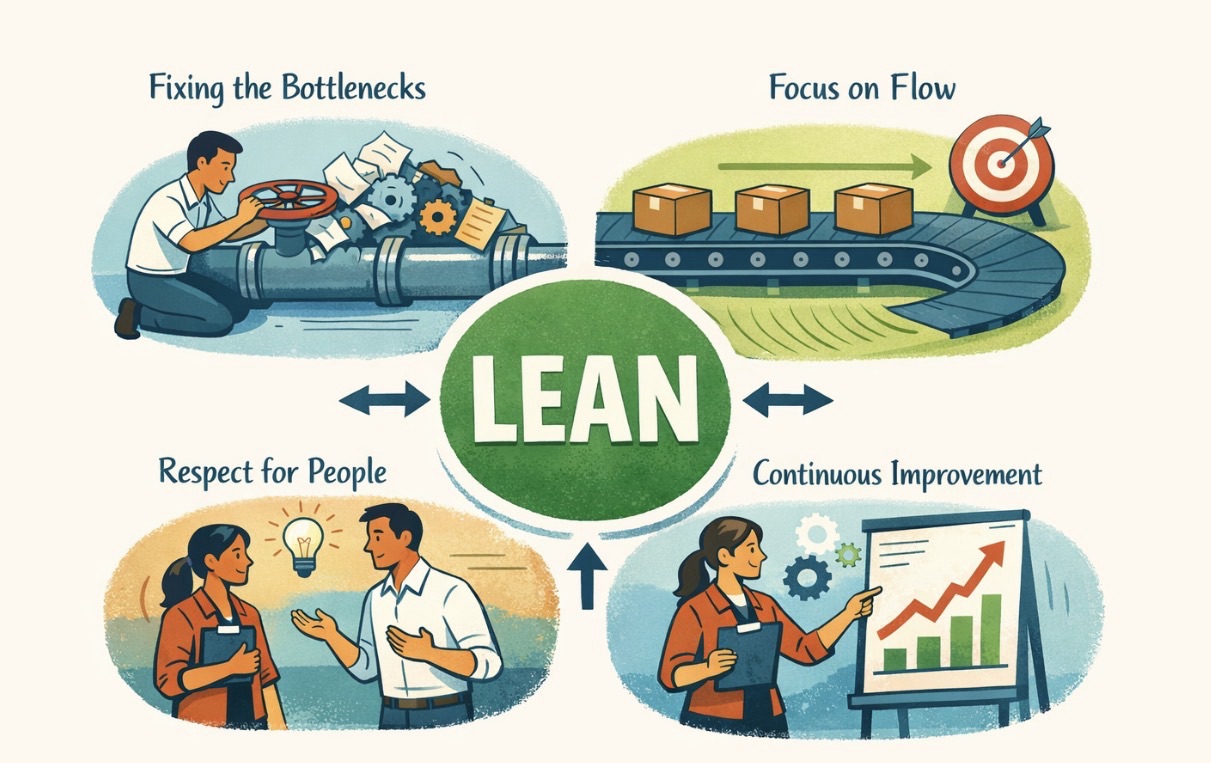

Why is this work harder than it needs to be?

Not who is at fault. Not how fast people should work. Just an honest look at friction—delays, rework, handovers, ambiguity—and a commitment to remove it.

When Lean fails, it’s usually because the conversation never gets past the tools. When it succeeds, the tools fade into the background and better decisions take centre stage.

Flow beats busyness

Many organisations are extremely busy and strangely unproductive at the same time. Work is started everywhere, progress is reported enthusiastically, and yet very little finishes.

Lean shifts attention from utilisation to flow. From “are people busy?” to “how quickly and reliably does value move through the system?”

That shift is uncomfortable. It exposes queues, dependencies, and the hidden cost of multitasking. But it also creates focus. Fewer priorities. Clearer trade-offs. Work that actually finishes.

Respect for people is not a slogan

One of Lean’s most quoted principles is “respect for people”. It’s also one of the most misunderstood.

This doesn’t mean being nice while pushing unrealistic targets. It means designing systems that allow capable people to succeed. Systems where problems are visible, speaking up is safe, and improvement is part of the job—not an extra task after hours.

Lean organisations don’t assume people are the problem. They assume the system is, and they work on it together.

Lean is a habit, not a programme

The biggest mistake is treating Lean as something you roll out.

Real Lean shows up in small, consistent behaviours:

Leaders asking better questions Teams fixing root causes instead of symptoms Decisions made closer to the work Learning captured and reused

There’s no finish line. Just a steady reduction in waste, frustration, and uncertainty over time.

The quiet advantage

Lean done properly doesn’t shout. It doesn’t need posters or jargon. You notice it in shorter lead times, calmer teams, and customers who get what they need without chasing.

In a noisy world full of transformation theatre, that quiet competence is a serious competitive advantage.

Chris@amberhill.biz

www.amberhill-associates.com