This year has been an extremely exciting & challenging one for me personally. In January 2014 I signed a 12 month contract with Tata Technologies as Lead Engineer in Exterior Trim developing & bringing to production Jaguar Land Rovers’s Freelander replacement the new ‘Discovery Sport’.

In January I was based in TTL’s Coventry office but spent a lot of time at JLR’s Browns Lane plant in the West Midlands, historical home of Jaguar Cars & now utilised as a Pilot Plant for small scale production.

Walking into Browns Lane was a great experience personally as I met many old friends from JLR having worked on the Range Rover Sport Programme. Although it is a large organization employing many thousands its amazing how many people you get to know working on a project for 18 months.

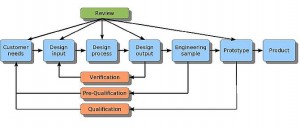

The pilot build is known as VP build & this stage of the process is very much a learning process. Some trim parts are still not ‘off tool’ & its all about capturing issues via the Automated Issues Management system. This AIMs system is used to track issues & ensure the proper fix is put in place before closure. It provides visibility to Senior Management & its administration is one of the Lead Engineer’s key tasks along with developing engineering solutions & working with key suppliers to ensure timely delivery of quality parts. Most issues require a PACN (to support financial justification) & a Engineering Release to implement the change. As most Engineers are responsible for numerous parts time is rapidly eroded before its time for the next build – Hard Tool Functional Build (HTFB)

This build took place at JLR’s Halewood plant where the Discovery Sport is to be mass produced & which was to be my base for the next 8 months.

Halewood is a large plant which covers several square miles & employs over 8,000 people. Most of the Product Coaches & Line Engineers were involved in the Browns Lane builds so there were many familiar faces at Halewood as well as plenty new ones. Halewood is one of JLR’s centres of excellence & the Engineering knowledge here is second to none.

Over the next 8 months we embarked on a number of builds increasing in numbers & complexity. This is a very stressful period for all & the nearer Volume Launch approaches the pressure piles on.

It was with a mixture of relief & a great sense of achievement when Volume Launch in December was achieved and cars began rolling off the production line at a rate of one every 40 seconds !!

It is important to recognise the economic importance of this model; Tata have invested hundreds of millions of pounds in this venture which has created several thousand jobs at Halewood & employed hundreds of thousands in the wider supply chain. With JLR’s commitment to source 60% of parts within a 40 mile radius the importance to the Regional Economy cannot be underestimated.

To play a small part in this great venture & to help take the Discovery Sport from initial concept to volume production brings a great sense of pride & achievement.

chris@amberhill.biz

There has been some debate in the Media recently about buying British products as a way of reducing the impact of the recession & preserving British jobs; so is this a good idea ?

There has been some debate in the Media recently about buying British products as a way of reducing the impact of the recession & preserving British jobs; so is this a good idea ?