There has been some debate in the Media recently about buying British products as a way of reducing the impact of the recession & preserving British jobs; so is this a good idea ?

There has been some debate in the Media recently about buying British products as a way of reducing the impact of the recession & preserving British jobs; so is this a good idea ?

We live in a Capitalist society (whether we like that or not) based on competition. The consumer has a free choice of which products to buy or not to buy & we tend to seek good value for money, regardless of origin. As a consequence we are pretty good at identifying products which deliver most “bang for the buck”.

In the 1970’s most of our Electronic products originated in Japan. Some people complained this wasn’t fair to British manufacturers but consumers continued to buy Japanese products because they were better quality and hence better value for money.

Now most of our electronic products are manufactured in China or Korea & people buy them because they are cheaper & better quality than their Japanese counterparts.

Jaguar Land Rover has been in the News recently because sales are up over 30% compared to last year, is this because these products are manufactured in Britain or because they are of exceptional quality and, though expensive, represent good value for money.

Over time products evolve and the companies which make them either grow – & their shareholders get richer or, if their products deteriorate the company shrinks, the shareholders lose money & eventually the company is bust.

So, in the long run, is the best way to preserve British jobs to buy inferior goods just because they are British or to buy the best value products whatever their origin & ensure quality increases & the fittest survive ?

www.projectsguru.co.uk

Projectsguru.co.uk

Promote your Page too

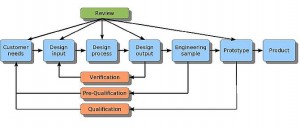

In the Automotive# industry thousands of individual components are designed, developed, prototyped, tested and tuned silmultaneously to be brought together as a finished car which has to meet exacting standards for safety, perfomance and reliability.

In the Automotive# industry thousands of individual components are designed, developed, prototyped, tested and tuned silmultaneously to be brought together as a finished car which has to meet exacting standards for safety, perfomance and reliability.

There has been some debate in the Media recently about buying British products as a way of reducing the impact of the recession & preserving British jobs; so is this a good idea ?

There has been some debate in the Media recently about buying British products as a way of reducing the impact of the recession & preserving British jobs; so is this a good idea ? 2012 has been a pretty miserable year with freakish weather on both sides of the Atlantic, in the U.K the highest rainfall since records began saw people washed out of house and home and businesses ruined. In the USA Hurricane Sandy battered the East Coast and several lives were lost, homes ruined & businesses destroyed.

2012 has been a pretty miserable year with freakish weather on both sides of the Atlantic, in the U.K the highest rainfall since records began saw people washed out of house and home and businesses ruined. In the USA Hurricane Sandy battered the East Coast and several lives were lost, homes ruined & businesses destroyed. Fantastic news today regarding the development of a National Automotive Innovation Campus at the University of Warwick.

Fantastic news today regarding the development of a National Automotive Innovation Campus at the University of Warwick. Governor Jerry Brown signed through legislation to allow fully automated vehicles on California’s roads.

Governor Jerry Brown signed through legislation to allow fully automated vehicles on California’s roads.