This week Jaguar Land Rover released the following press statement:-

This week Jaguar Land Rover released the following press statement:-

Tag Archives: manufacturing

What is #Quality ?….

Quality has a number of definitions, ‘fit for purpose’, ‘exceeding expectations’ ‘meeting specifications’. It can be a tricky thing to measure but we all know it when we perceive it.

Quality has a number of definitions, ‘fit for purpose’, ‘exceeding expectations’ ‘meeting specifications’. It can be a tricky thing to measure but we all know it when we perceive it.

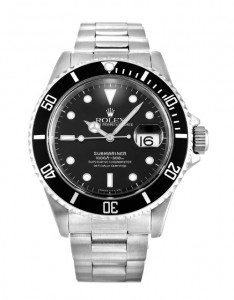

Take a Rolex watch for example, the materials used in its construction, its finish, its mechanical integrity all tell us it is a ‘Quality’ item – this is naturally reflected in its price.

Although lots of fakes exist it is impossible to replicate the original without investing the same levels of workmanship and materials into it’s manufacture. This gives us a clue as to the origin of the Quality of the object. It lies in the specification & manufacture of the object within a given set of tolerances.

This is reflected in the luxury end of the automotive industry where body panels are specified as beng within a tight dimensional tolerance which in previous generations of product may have been deemed impossible.

Such tolerances lead to a vehicle which is perceived as high Quality without the buyer neccesarily understanding why.

So, if we can capture the expectations of the customer & translate them into product specifications with tolerances we can design & build something which has increased added value & perceived customer Quality.

#Lean empowerment……

At the heart of the Toyota Production System (sometimes referrred to as #Lean Production System) is the principle of ‘Jidoka’.

According to Toyota “Jidoka means that a machine safely stops when the normal processing is completed. It also means that, should a quality / equipment problem arise, the machine detects the problem on its own and stops, preventing defective products from being produced. As a result, only products satisfying quality standards will be passed on to the following processes on the production line.”

But there is more to #Lean than this. The key component is the empowerment of the Operator to stop the process immediately a defect or potentialy defective process is discovered without referring the issue upward. The Operator can stop the production process without fear of retribution and is empowered to do so. This is a great responsibility and one which is not granted lightly, the Operator must be fully trained and the Organisation steeped in the culture of #Lean & #Kaizen (continuous improvement)

Granting this autonomy is absolutely key to the success of the TPS philosophy & unleashes immense forces of creativity & quality improvement.

Projectsguru.co.uk

Promote your Page too

10 tips to minimize cost at the Design stage….

All companies need to be mindful of costs & for those producing products this is best done at the Design stage. Here are some suggestions:-

All companies need to be mindful of costs & for those producing products this is best done at the Design stage. Here are some suggestions:-

- Before beginning the design a Product Specification is essential, this needs to have been agreed at Senior Management level.

- The product design needs to meet the spec and no more.

- The material choice is critical, why make it out of gold if steel will do.

- Use minimum thickness, as long as the design meets the spec.

- Reduce the number of components as much as possible.

- Re-use existing design components wherever possible – this gives Purchasing negotiating strength over suppliers and reduces inventory.

- Consider Manufacturing by minimizing the number of process steps in manufacture.

- Hold regular Design reviews & involve other parts of the Organization.

- Build a prototype to test the design.

- If possible test the Design using Computer Aided Modelling.

If you need help minimizing cost at the Design stage feel free to get in touch.

chris@projectsguru.co.uk

![]()

Projectsguru.co.uk

Promote your Page too

Bentley – made in Crewe, England

The News from Volkswagen Group this week that Bentley’s new luxury SUV will be built in Crewe, England is welcome news indeed, not only for Bentley Motors Ltd but also for the North West of England and the area’s supply chain.

Volkswagen Group (owner of Bentley) is investing over 800m GBP in the new SUV and creating around 1000 jobs in Bentley & the local suppl y chain.

y chain.

This illustrates the Group’s faith in the Engineering & build quality of Bentley as it was rumored that it could be built in Brataslava alongside the Audi Q7 & Porsche Cayenne.

It is likely the car will enjoy a facelift as the EXP9F prototype received mixed reviews at the Geneva Motor Show.

chris@projectsguru.co.uk

![]()

#Automotive Competitive Sport………

Today Jaguar Land Rover revealed the all new Range Rover Sport in Manhattan New York. This fabulous vehicle is a terrific example of British Engineering at it’s best. The West Midlands manufacturer goes from strength to strength with double digit sales growth across the globe.

Rumour has it that JLR could sell their entire manufacturing capacity for the new Sport to China alone.

The new Range Rover sport is built to ultimate quality standards and features many examples of innovative design, from the all aluminium body shell (which is half a ton lighter than the previous model saving 15% in fuel) to the class leading infotainment system.

JLR are leading the world in automotive product design and manufacture. Long may it continue.

![]()

Projectsguru.co.uk

Promote your Page too

Your #business cannot compete on cost alone…

According to new research published today by Allianz Insurance, some 83% of UK managers rank Innovation as the key to their organization performing strongly.

However, despite the fact most leaders are fully aware of the benefits of innovation, the ongoing challenging economic environment has caused many to opt out of such projects in recent months.

For instance, 23% of the 500 respondents noted that the economic slump has pushed innovation further down their list of business priorities, with issues such as a lack of funding and a focus on profits being the main reasons behind this fact.

This approach is not only wrong it is patently short sighted. Innovating value added products or services is the only way to ensure long term survival never-mind success. Long-term it is not possible for organizations to compete purely on cost. Globalization ensures that whenever you compete purely on cost, someone, somewhere will be able to undermine your cost base and do it cheaper. The only way to compete successfully, particularly in the West, is to produce differentiated products with high added value, which cannot be easily reproduced elsewhere where labor costs are significantly cheaper.

This requires investment in R & D, training and advanced manufacturing techniques.

Innovation is essential to long term survival.

chris@projectsguru.co.uk

![]()

Invasion of the Robot cars….#auto #innovation

Last week saw a little reported milestone in Automotive history when Californian  Governor Jerry Brown signed through legislation to allow fully automated vehicles on California’s roads.

Governor Jerry Brown signed through legislation to allow fully automated vehicles on California’s roads.

This took place at Google’s ‘Mountainview’ headquarters where the team have been working on a car which utilizes Google’s ‘Street View’ mapping technology, a number of sensors & some clever software to enable the car to navigate without human intervention. The company has already done over 300,000 miles testing with zero collisions so far.

So why is all of this so important ?? As Highways get increasingly congested it has long been a dream to enable convoys of vehicles to travel nose to tail in close proximity in separate lanes, breaking off as necessary, to reach local destinations.

Robot cars may smack of Sci-Fi but this development could herald a massive social change and a glimpse of the future.

![]()

#Auto output drives toward production record

The UK automotive industry is set to break its all time production record of 1.92 million cars (set in 1970!!) in 2015. These figures are from the Society of Motor Manufacturers & Traders.

The UK automotive industry is set to break its all time production record of 1.92 million cars (set in 1970!!) in 2015. These figures are from the Society of Motor Manufacturers & Traders.

This success is hard won and it has been a long upward climb to return to the heights of the 1970’s. It is hard to believe that UK auto manufacturing then represented approximately a 10% world share. Now it is just over 2%.

A heck of a lot of ground was lost following the 1973 oil crisis and the gradual decline of British Leyland.

Success now depends on innovative Product Design. Take a look at Jaguar Land Rover’s Evoque (see above) which has sold over 100,000 units in it’s first year and has led to 24/7 manufacture at the Halewood plant.

Another great example is BMW’s mini which is turned out at it’s expanded Oxford plant.

Manufacturing in the UK Automotive industry has been revolutionized since the sad days of the 1970’s, much of this led by Nissan in the North East with the adoption of Japanese manufacturing techniques such as LEAN & JIT.

If we can capitalize on current success the UK Automotive industry has a terrific future.

; Keep up to date by becoming a facebook

fan

Jaguar Land Rover has a taste for Chinese #automotive

A new sales record of over 314k cars and profits of 1.5 billion GBP illustrate the success of British car maker Jaguar Land Rover and it’s innovative new products including the Range Rover Evoque which is selling like “hot cakes” at the moment particularly in China. In fact Jaguar Land Rover is opening a new dealership in China every week. China sales now represent almost 20% of the companies sales.

A new sales record of over 314k cars and profits of 1.5 billion GBP illustrate the success of British car maker Jaguar Land Rover and it’s innovative new products including the Range Rover Evoque which is selling like “hot cakes” at the moment particularly in China. In fact Jaguar Land Rover is opening a new dealership in China every week. China sales now represent almost 20% of the companies sales.

There is, however, another less publicised side to this story.

Since 2007 the British Pound has devalued against the Chinese Yuan (or RMB) by a whopping 56% as a direct result of the U.K Governments policy of Quantitative Easing. In March 2009 75 billion pounds was created electronically followed by another 200 billion pounds later that year. Further episodes of Q.E pumped a total of 325 billion pounds into the U.K economy, devaluing the pound & increasing exports.

It also goes a long way to explaining why foreign ownership of London property has increased 20% since 2009 & conversely why imported foodstuffs & other goods now seem outrageously expensive.

; Keep up to date by becoming a facebook

fan