Whatever the rights or wrongs of the killing of Osama Bin Laden the message delivered surrounding his dispatch was certainly confusing to say the least.

Whatever the rights or wrongs of the killing of Osama Bin Laden the message delivered surrounding his dispatch was certainly confusing to say the least.

First he died in a vicious firefight, next he was unarmed.

He used his wife as a human shield, then it was her who leaped in front of him!

The Whitehouse staff watched every moment of the assault live, then…… oh no they didn’t, they only watched the first couple of minutes before transmission was lost ! etc etc etc etc

“Jeeeezzzzzz! can’t these guys get anything right? ” millions around the world screamed at their TV’s.

And this is just the kind of mixed messages we deliver to our exasperated customers every day of the week. First we promise delivery on a certain date, then we go back and revise it, then someone else tells them a different story, its hardly any wonder that customers get fed up and go elsewhere.

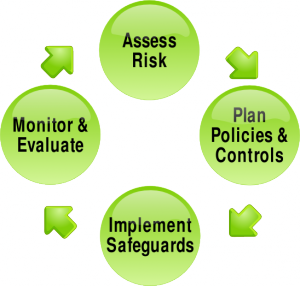

So here are some simple tips to make sure your organization is on message for your customers:-

1) Where possible have one direct contact per customer, if this is not feasible have one contact for engineering issues, another for commercial etc.

2) Before giving a customer a key milestone make sure the project plan is fully developed and includes some contingency to allow for risk.

3) If events transpire to affect a key customer milestone make sure every option is explored to pull back on track before going back to the customer with the bad news.

4) If a major milestone is affected this should be communicated face to face.

5) Always give the customer a series of alternative options, so they can choose the best for them.

Keeping the customer on message is an essential part of managing customer relations and ensuring steady, repeat business.

![]()

; Keep up to date by becoming a facebook

fan

This week one of the busiest Motorways in England was closed for 3 days because of a fire in a scrap yard adjoining the motorway. In the ensuing debate questions were raised about the need to prevent such a thing happening again, including closing all potential threats in sites adjoining Motorways.

This week one of the busiest Motorways in England was closed for 3 days because of a fire in a scrap yard adjoining the motorway. In the ensuing debate questions were raised about the need to prevent such a thing happening again, including closing all potential threats in sites adjoining Motorways. 5o years ago today Yuri Gagarin became the first man in space when he orbited the earth in his Vostok spacecraft, winning the cold war race and catapulting himself into the annals of history.

5o years ago today Yuri Gagarin became the first man in space when he orbited the earth in his Vostok spacecraft, winning the cold war race and catapulting himself into the annals of history.

On a recent business trip to Geneva I flew from Leeds Bradford Airport in the North of England. I checked through on time and headed for the gate to be met by a scene of organised chaos. The queue was very long and heaving with Schoolkids on exchange visits, holidaymakers and business people. At the very end of this long queue we were given a tray into which we had to load our laptops, keys, belts etc as part of the security screening process. This was undoubtedly the bottleneck and by the time I got through security to the Gate I was informed by an attendant that I may well have missed the flight. I was then subjected to admonishment, had I not heard the attendants calling people through for the Geneva flight – “No” , I hadn’t heard anything in melee – anyway to cut a long story short I caught my flight but not without a lot of hassle and stress.

On a recent business trip to Geneva I flew from Leeds Bradford Airport in the North of England. I checked through on time and headed for the gate to be met by a scene of organised chaos. The queue was very long and heaving with Schoolkids on exchange visits, holidaymakers and business people. At the very end of this long queue we were given a tray into which we had to load our laptops, keys, belts etc as part of the security screening process. This was undoubtedly the bottleneck and by the time I got through security to the Gate I was informed by an attendant that I may well have missed the flight. I was then subjected to admonishment, had I not heard the attendants calling people through for the Geneva flight – “No” , I hadn’t heard anything in melee – anyway to cut a long story short I caught my flight but not without a lot of hassle and stress. How many times have you worked on projects where the product spec is not defined?

How many times have you worked on projects where the product spec is not defined?

As a rough guide a

As a rough guide a