The response of most companies to the current recession has been a round of savage cost cutting in the form of job loses, wage freezes, caps on pay etc etc

The response of most companies to the current recession has been a round of savage cost cutting in the form of job loses, wage freezes, caps on pay etc etc

Of course this is understandable given the size of the slump following the global financial crisis but any company which believes that cost cutting alone will enable them to survive in the long term is sadly misguided.

The only way to grow is by introducing innovative products and services with real customer demand that beat the competition.

Companies that rely on cost cutting alone and who hope to deliver the same old same old will whither and die. The insolvency graveyard is full of companies which lacked the vision to change and, like a dinosaur which could not adapt to changing times, ultimately ceased to exist.

Some of the best examples of innovation can be seen in the Great Depression of the 1930’s. DuPont invested heavily in Research & Development. By the late 1930’s 40% of its sales were from products that were less than a decade old, including Nylon & synthetic rubber.

Procter & Gamble invested so heavily in Radio advertising it invented a new art form – The Soap Opera.

In the current resession Asda is building 14 new stores & hiring 7000 new workers. PepsiCo has taken direct control of two of its bottling plants at a cost of $6 billion.

Despite seeing it’s revenues fall by 23% in Q4 2008 compared to Q4 2007  Intel is continuing to invest heavily in innovation.

Intel is continuing to invest heavily in innovation.

Cisco is buying up start-ups left right and centre.

P&G is undergoing its biggest expansion is 170 years opening 19 new factories world wide.

Innovation is the only answer for long term growth.

chris@amberhill.biz

Recent news that GM has failed to find a buyer for Saab leading to the imminent demise of this once great automotive manufacturer will sadden those of us who once owned one of these iconic vehicles.

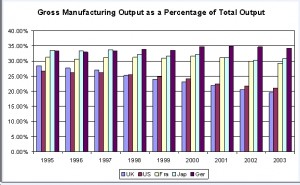

Recent news that GM has failed to find a buyer for Saab leading to the imminent demise of this once great automotive manufacturer will sadden those of us who once owned one of these iconic vehicles. Its common knowledge in the U.K that manufacturing has declined over several years but the attached graphic illustrates just how serious that decline is compared to other leading nations. The situation after the credit crunch is likely to paint an even grimmer picture.

Its common knowledge in the U.K that manufacturing has declined over several years but the attached graphic illustrates just how serious that decline is compared to other leading nations. The situation after the credit crunch is likely to paint an even grimmer picture.