Bringing New Products to Market faster & more efficiently is even more critical as product life-cycles shrink so here are 10 tips for faster, leaner New Product Development:-

1) Nail the spec early – the sooner the product spec is finalised the smoother & faster the development will be. Less time & effort will be wasted debating the minutiae if the spec is closed early.

2) 5s the area – Apply the Lean principles of 5s (see earlier post) to remove unnecessary distraction and promote “clear thoughts”

3) Promote re-use in Design – to reduce design effort and make best use of proven and qualified technology.

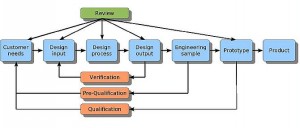

4) Parallel Planning & Design – Design is normally the longest phase in New Product Development so why wait until the end of Planning to start Design. Start Design in parallel and adapt the plan when more is known about the length of the design phase.

5) Arrange Regular Reviews – during the Design phase and break the task into smaller “chunks”. Design is one of those tasks which has a tendency to expand to fill the time allowed for it.

6) Structure the Innovation process – ensure that Innovation board reviews are scheduled well in advance and board members have suitably qualified deputies so that stage gate reviews suffer no delays due to the absence of key personnel. The Innovation process should become Institutionalized.

7) Dedicated multifunctional Teams – are more effective than matrix teams If resource allows.

8) Design for Manufacture – manufacturing & production engineers need to be involved in the product development process to ensure a smooth transition from development to manufacture.

9) Minimize interruptions & noise – in the product development area.

10) Promote a democratic involving Management style – to increase free discussion and mutual respect.

In their iconic book “Lean Thinking” Womack & Jones identified 5

In their iconic book “Lean Thinking” Womack & Jones identified 5

First of all please let me apologize for the use of the word “buggers” which some of you may find offensive but I just couldn’t think of another term (apart from an even more offensive B term) to describe those people who are just plain damn awkward.

First of all please let me apologize for the use of the word “buggers” which some of you may find offensive but I just couldn’t think of another term (apart from an even more offensive B term) to describe those people who are just plain damn awkward.

The Mac TV was released in 1993 and was Apple’s first attempt to integrate the functionality of a P.C with a cable ready T.V. Unforthunately it’s slow bus speed of 16 MHz made for a slow P.C compared to it’s rivals and a very expensive T.V at over $2000. Needless to say it flopped and only 10k were produced.

The Mac TV was released in 1993 and was Apple’s first attempt to integrate the functionality of a P.C with a cable ready T.V. Unforthunately it’s slow bus speed of 16 MHz made for a slow P.C compared to it’s rivals and a very expensive T.V at over $2000. Needless to say it flopped and only 10k were produced. Apple’s first attempt at a portable computer was the Macintosh portable. Released in 1989 it was way ahead of its time, and so it should have been at a whopping $6500. It weighed in at a hefty 7.2kg and had an active matrix LCD screen which was fantastic but the major contributor to its cost.

Apple’s first attempt at a portable computer was the Macintosh portable. Released in 1989 it was way ahead of its time, and so it should have been at a whopping $6500. It weighed in at a hefty 7.2kg and had an active matrix LCD screen which was fantastic but the major contributor to its cost. In 1995 Apple licensed its PIPPIN technology to Bandai to make a PC based game consol. The only problem was the competition, SEGA, SONY, Nintendo and PC based systems were already dominating the market. Only 42,000 PIPPIN units sold and it was withdrawn from the market.

In 1995 Apple licensed its PIPPIN technology to Bandai to make a PC based game consol. The only problem was the competition, SEGA, SONY, Nintendo and PC based systems were already dominating the market. Only 42,000 PIPPIN units sold and it was withdrawn from the market. If you need a

If you need a  Whilst the football may not have lived up to the hype so far we have still seen a couple of excellent team performances. So what is it that makes for a

Whilst the football may not have lived up to the hype so far we have still seen a couple of excellent team performances. So what is it that makes for a  We are conditioned to fear failure. We must succeed at all costs. Throughout our schooling we are expected to pass our exams with flying colours and to fail is to be labelled as useless.

We are conditioned to fear failure. We must succeed at all costs. Throughout our schooling we are expected to pass our exams with flying colours and to fail is to be labelled as useless.