Effective Project Management.

What is a Project ?

A project may be large or small, simple or complex but all projects share three common attributes:-

• Specific Outcomes – the project is set up to deliver some specific results or outputs.

• Defined Start & End dates – The project starts and finishes on pre-defined dates.

• Budget – the project has a pre-defined budget which it should not exceed

What is the Project Management process.

There are a multitude of definitions of the project management process but all of them share the attributes shown below:-

The Role of the Project Manager.

The role of the project manager is a challenging one. Often he or she will be coordinating the activities of technical highly skilled people and liaising with internal and external parties all critical to project delivery. Project Management is a highly skilled professional role and the Project Manager will normally need several years experience in order to be successful.

The role involves the key tasks of planning, organizing and controlling. In complex projects planning project tasks often involves the use of software programs such as Microsoft Project which enables the Project Manager to schedule hundreds of tasks and manipulate their interdependencies in order to reduce the overall timescale of the project.

Organizing involves dealing with people within the immediate project team as well as third parties internal and external to the wider organization.

Controlling involves monitoring and measuring outputs and exerting influence to achieve the desired outcomes.

In order to be effective the Project Manager needs information, communication and commitment.

chris@projectsguru.co.uk

www.projectsguru.co.uk

In a press statement released today at 21.oo GMT Father Christmas announced that, from today onwards, all toys will be manufactured by Chinese elves due to the increasing costs of employing elves at the North Pole. This has been exacerbated due to the effects of global warming and the shrinking ice cap making Real estate in the Northern Latitudes increasingly expensive.

In a press statement released today at 21.oo GMT Father Christmas announced that, from today onwards, all toys will be manufactured by Chinese elves due to the increasing costs of employing elves at the North Pole. This has been exacerbated due to the effects of global warming and the shrinking ice cap making Real estate in the Northern Latitudes increasingly expensive. Recent news that GM has failed to find a buyer for Saab leading to the imminent demise of this once great automotive manufacturer will sadden those of us who once owned one of these iconic vehicles.

Recent news that GM has failed to find a buyer for Saab leading to the imminent demise of this once great automotive manufacturer will sadden those of us who once owned one of these iconic vehicles. It is common in Organizations to look for someone to blame when things go wrong. Some cultures are more prone to this behaviour than others but the temptaion to blame a member of the team when things go awry should be strongly resisted by the Project Manager.

It is common in Organizations to look for someone to blame when things go wrong. Some cultures are more prone to this behaviour than others but the temptaion to blame a member of the team when things go awry should be strongly resisted by the Project Manager. The recent events in Dubai, where the state owned fund “Dubai World” announced it needed an additional 6 months to repay some of its outstanding debt, caused shockwaves around the World echoing the problems of Lehmans 12 months ago. The impact was felt on stock exchanges from Hong Kong to Wall Street.

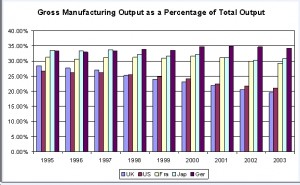

The recent events in Dubai, where the state owned fund “Dubai World” announced it needed an additional 6 months to repay some of its outstanding debt, caused shockwaves around the World echoing the problems of Lehmans 12 months ago. The impact was felt on stock exchanges from Hong Kong to Wall Street. Its common knowledge in the U.K that manufacturing has declined over several years but the attached graphic illustrates just how serious that decline is compared to other leading nations. The situation after the credit crunch is likely to paint an even grimmer picture.

Its common knowledge in the U.K that manufacturing has declined over several years but the attached graphic illustrates just how serious that decline is compared to other leading nations. The situation after the credit crunch is likely to paint an even grimmer picture.